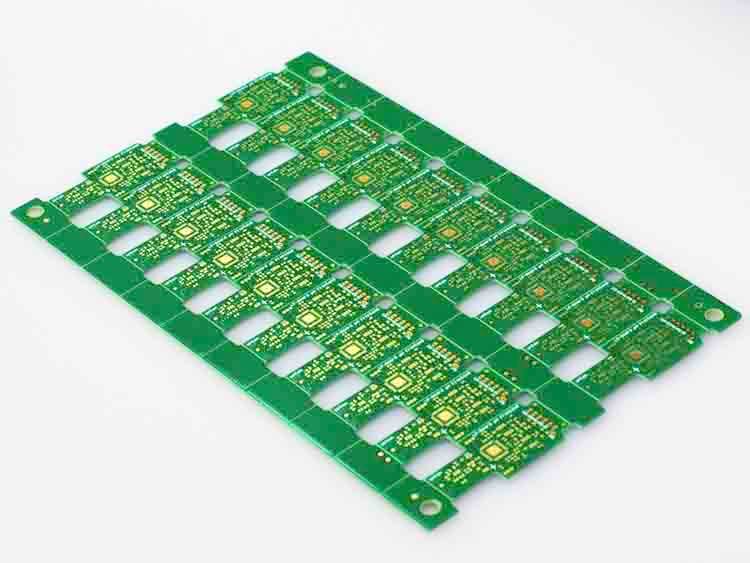

PCB Manufacturing

We manufacture Rigid, Flexible, and Ultra-dense electronic circuits using the latest manufacturing technologies and following the highest standards of quality and safety.

HLA Line

PCB Manufacturing

We manufacture Rigid, Flexible, and Ultra-dense electronic circuits using the latest manufacturing technologies and following the highest standards of quality and safety.

HLA Line

PCB Manufacturing

We manufacture Rigid, Flexible, and Ultra-dense electronic circuits using the latest manufacturing technologies and following the highest standards of quality and safety.

HLA Line

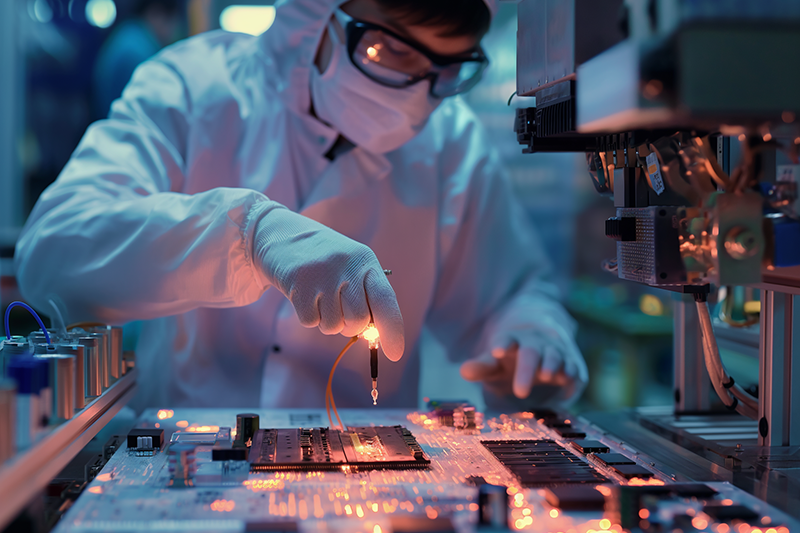

PCB Manufacturing

We manufacture Rigid, Flexible, and Ultra-dense electronic circuits using the latest manufacturing technologies and following the highest standards of quality and safety.

HLA Line

PCB Manufacturing

We manufacture Rigid, Flexible, and Ultra-dense electronic circuits using the latest manufacturing technologies and following the highest standards of quality and safety.

HLA Line

PCB Manufacturing

We manufacture Rigid, Flexible, and Ultra-dense electronic circuits using the latest manufacturing technologies and following the highest standards of quality and safety.

HLA Line

Manufacturing Capabilities

-

Number of layers: 1 – 52

-

Materials: High performance FR4, rigid polyimide, low loss hydrocarbon, low loss PTEF

-

Copper weights (finished): 18 μm – 105 μm

-

Minimum line/space: 0.075 mm / 0.075 mm

-

Minimum core thickness: 0.1 mm

-

Thickness range: 0.6 mm – 3.2 mm

-

Available panels dimensions: 610×457 or 560×457

-

Surface finishes available: HASL, LF HASL, OSP, ENIG

-

Minimum mechanical drill: 0.15 mm

-

Number of layers: 1 – 4 L

-

Materials: Flex polyimide

-

Copper weights (finished): 18 μm – 35μ

-

Minimum line/space: 0.075 mm / 0.075 mm

-

Minimum core thickness: 0.025 mm

-

Thickness range: 0.03 mm – 0.1 mm

-

Available panels dimensions: 610×457 or 560×457

-

Surface finishes available: OSP, ENIG

-

Minimum mechanical drill: 0.15 mm

-

Minimum laser drill: 0.075 mm

-

Number of layers: 4-16 layers

-

Materials: High performance FR4, Rigid polyimide, Flex Polyimide

-

Copper weights (finished): 18 μm – 70 μm

-

Minimum line/space: 0.075 mm / 0.075 mm

-

Minimum core thickness: For Flex (0.025 mm) For Rigid (0.1 mm

-

Thickness range: 0.4 mm – 3.2 mm

-

Available panels dimensions: 610×457 or 560×457

-

Surface finishes available: OSP, ENIG

-

Minimum mechanical drill: 0.15 mm

-

Minimum laser drill: 0.075 mm

-

Number of layers: 1 – 52

-

Materials: High performance FR4, rigid polyimide, low loss hydrocarbon, low loss PTEF

-

Copper weights (finished): 18 μm – 105 μm

-

Minimum line/space: 0.075 mm / 0.075 mm

-

Minimum core thickness: 0.1 mm

-

Thickness range: 0.6 mm – 3.2 mm

-

Available panels dimensions: 610×457 or 560×457

-

Surface finishes available: HASL, LF HASL, OSP, and ENIG

-

Minimum mechanical drill: 0.15 mm

-

Minimum laser drill: 0.05 mm

| Plated Through Hole | Minimum finished diameter 150 μm-Aspect Ratio for PTH: ≤ 15 |

| Blind Micro via | Minimum diameter 50μm (laser drilled) -Aspect Ratio for blind vias: ≤ 1 |

| µVias Treatment | Capped through vias and resin filled blind vias, Copper filled |

| Fine Line | Minimum track/spacing is 50 μm, ±10 tolerance |

| Layer Count | Standard up to 32, special requirement up to 50 after DFM evaluation |

| Flexible Layer Count | Up to 16 inner layers in a Rigid-Flex build up, special requirement after DFM evaluation |

| Sequential Lamination | Up to 3+N+3 (SBU), special requirement after DFM evaluation |

| Base Cu Thickness | Thin copper 9 μm, 12 μm, 18μm, 35 μm, 70 μmup to 105μm. |

| Minimum Inner Layer Thickness | 50 μm, special requirement after DFM evaluation |

| Minimum Prepreg Thickness | 50 μm(1 x PP106) or lower but after DFM evaluation (PP1027 or Pp1037) |

| Maximum PCB Thickness | Standard 3.2mm special requirement up to 5.2 mm after DFM evaluation |

| Maximum PCB Dimensions | Multilayer: 420 x 525 mm, SS,DS 420X585 |

| Solder Mask | Spray Coating or screen printed (Green, Blue, Black, Red & White) |

| Solder Mask Capability | Solder Dam 75 μm standard and 50 μm special; Clearance down to 50 μm. |

| Vias Treatment | Tenting and plugging process like per IPC classification |

| Printing Application | Legend, Peelable mask. |

| Finishing | HASL with/without Lead; ENIG, OSP ; As per special requirements. |

| ITEM | DESCRIPTION | STANDARD | ADVANCED | CUTTING EDGE |

| Track & Gap | Line / Space inner | 100 | 75 | 50 |

| Line / Space inner | 100 | 75 | 60 | |

| Minimum Outer Layer Annular Ring (OAR) on Production Hole Diameter (PHD | 150 | 100 | 75 | |

| Minimum Inner Layer Annular Ring (IAR) / Thermal Annular Ring on PHD | 150 | 100 | 75 | |

| Hole Diameter | Minimum Production Hole Diameter (PHD) for thickness 1.6 mm (Others: see table) | 200 | 150 | 150 |

| Maximum aspect ratio PTH: see also table (Thickness / PHD) | 8 | 12 | 15 | |

| μVia –Buried | Minimum blind μvia drill diameter -material with glass | 150 | 100 | 50 |

| Maximum blind μviaaspect ratio | 1 | 1 | 1.2 | |

| Minimum blind μvia drill diameter -material without glass | 125 | 100 | 50 | |

| μViatop pad annular ring | 150 | 100 | 75 | |

| μVialanding pad annular ring | 150 | 100 | 75 | |

| Maximum number of stack via | 1 | 2 | 3 | |

| Drill \Cu Distance | PTH to cu on inner layers (means IAR + Value) | 250 | 200 | 150 |

| NPTH to cu on inner layers /NPTH Routing always>250 μm(means IAR+Value) | 250 | 200 | 150 | |

| NPTH to cu on outer layers ( NPTH Routing always >200 μm) | 250 | 200 | 150 | |

| Routing Tolerance | 200 | 200 | 100 | |

| Solder Mask | Solder mask Registration +\-40 μm | +\-40 | +\-40 | +\-40 |

| Solder mask Thickness Above copper >=5 μm | >=5 | >=5 | >=5 | |

| Minimum SM DAM | 150 | 100 | 50 | |

| Build up | Maximum PCB thickness (mm) | 3.2 | 3.2 | 3.2 |

| Minimum PCB thickness tolerance (%) | 10 | 10 | 10 | |

| Maximum number of Layers for Rigid-Flex PCB | 8 | 12 | 16 |

| Material for Rigid PCB | Material for Flex PCB | High Frequency Materials |

| Isola 402, Isola 185Hr | DuPont PyraluxAP | Roger 3000 Series |

| Panasonic Megtron6 Isola P95 (Rigid Polyimid) | DuPont PyraluxLF | Roger 4000 Series |

| Any other material for special requirements. | Any other material for special requirements. | Any other material for special requirements. |